What Size Gravel to Use for Paver Base

Creating a stable, long-lasting patio, walkway, or driveway begins with one critical factor: the right gravel base. Choosing the correct gravel size ensures proper compaction, drainage, and support for your pavers, which is essential for a successful patio paver installation. Selecting the wrong size can lead to uneven surfaces, sinking, and expensive repairs down the line.

Short Answer: What Size Gravel to Use for Paver Base

Most professionals recommend ¾-inch crushed stone (also called “¾ minus”) as the standard for paver bases. This size provides excellent compaction, supports heavy loads, and allows water to drain efficiently. Stones larger than 1 inch often fail to compact evenly, while smaller stones below ½ inch may settle too much under weight.

Example: For a 10×10 patio, a 4-inch deep base of ¾-inch crushed gravel is typically sufficient to create a stable foundation that supports outdoor furniture and foot traffic.

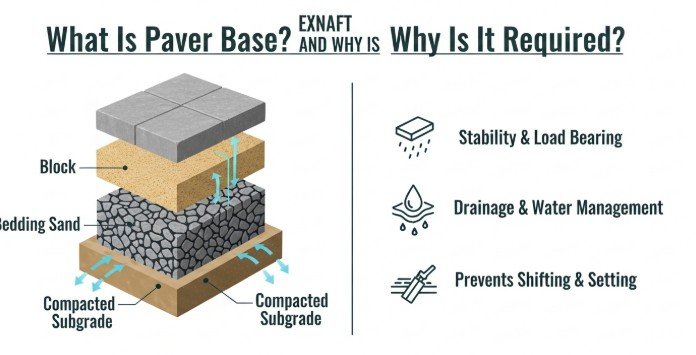

What Is Paver Base Gravel and Why Size Matters

Paver base gravel is the layer of crushed stone or aggregate installed directly under pavers. Its primary purpose is to:

Distribute weight: Prevents sinking or shifting under furniture, foot traffic, or vehicles.

Support drainage: Water flows through the gravel rather than pooling on the surface.

Protect against frost heave: Especially important in cold climates with freeze-thaw cycles.

Gravel vs Crushed Stone vs Sand

Gravel: Rounded stones, may not interlock; less stable.

Crushed stone: Angular, compacts tightly, ideal for paver bases.

Sand: Provides a smooth bedding layer but cannot replace gravel for structural support.

How gravel size affects your project:

Compaction: Larger stones (>1 inch) may leave voids; smaller stones (<½ inch) may settle.

Stability: ¾-inch gravel locks together to create a firm base.

Drainage: Proper-sized gravel allows water to flow freely, preventing pooling or erosion.

Why Choosing the Right Gravel Size Matters

Structural Integrity: Correct gravel prevents pavers from shifting or sinking.

Drainage: Proper sizing ensures water flows away efficiently.

Longevity: Reduces maintenance and extends the life of your patio or driveway.

Safety: Prevents uneven surfaces and tripping hazards.

Cost Efficiency: Avoids over-ordering or needing costly repairs due to incorrect base material.

What Size Gravel to Use for Paver Base (By Project Type)

Patios

Recommended size: ¾-inch crushed gravel

Load expectations: furniture, light foot traffic

Walkways & Paths

Recommended size: ½–¾ inch

Foot traffic only; easier to level

Driveways

Recommended size: ¾–1 inch

Vehicle load requires more support and compaction

Poor Soil or Cold Climate Areas

Adjust gravel size or use layered bases (smaller stones on top of larger ones)

Freeze-thaw cycles require deeper and well-compacted bases

Selecting and Using Gravel for Paver Base

Step 1: Assess Your Project Type and Load

Patios, walkways, and driveways have different load requirements.

Consider soil type: clay vs sandy soil affects drainage and compaction.

Climate: Freeze-thaw cycles require thicker, well-compacted bases.

Step 2: Choose Correct Gravel Size

¾-inch standard for most projects

Blended gravel (e.g., ¾ minus) fills gaps, increasing compaction

Larger stones for driveways, smaller for walkways

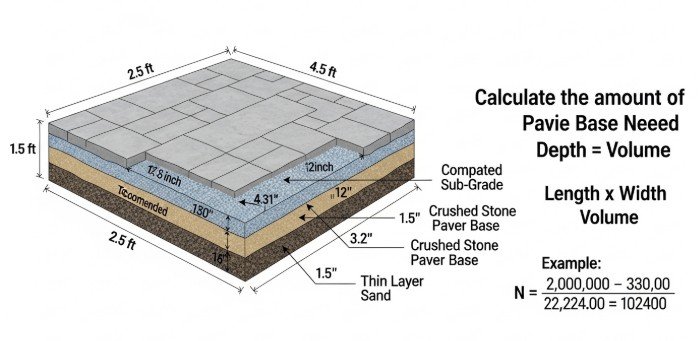

Step 3: Measure Area and Calculate Gravel Needed

Formula: Area (sq ft) × Depth (ft) × Compaction allowance

Real-world examples:

10×10 patio → 4-inch deep ¾-inch gravel → approx. 1.25 cubic yards

20×4 walkway → 3-inch deep ½–¾ inch gravel → approx. 0.67 cubic yards

12×20 driveway → 6-inch deep ¾–1 inch gravel → approx. 2.22 cubic yards

Step 4: Layer and Compact Gravel Properly

Recommended layer thickness: 2–3 inches per layer

Compact each layer with a plate compactor

Avoid over-layering or skipping compaction

Step 5: Add Sand Bedding Layer (Optional)

Fine sand on top of gravel provides smooth paver setting

Ensure correct thickness (½–1 inch)

Level carefully for interlock and uniform surface

Gravel Sizes for Paver Base

| Gravel Size | Compaction Quality | Drainage | Best Use Case | Pros | Cons |

|---|---|---|---|---|---|

| ½-inch | Medium | Good | Walkways, light patios | Easier to level | Less support for heavy loads |

| ¾-inch | High | Excellent | Patios, driveways | Standard recommendation | Requires proper compaction |

| 1-inch | Very High | Excellent | Driveways, heavy traffic | Superior load distribution | Harder to level, may need smaller top layer |

| Mixed / ¾ minus | High | Excellent | All-purpose | Fills gaps, stable | Slightly more expensive |

Bagged vs Bulk Gravel for Paver Base

Bagged Gravel: Convenient for small projects; higher cost per unit

Bulk Gravel: Economical for large areas; requires delivery and storage space

Tip: Choose based on project size and accessibility

Common Mistakes When Choosing Gravel Size

Using rounded gravel instead of crushed

Selecting stones that are too small or too large

Skipping compaction between layers

Ignoring soil conditions or climate impacts

People Also Ask

Can I use pea gravel for paver base?

Does gravel size affect drainage?

What is the best gravel size for a driveway?

Can I mix gravel sizes for paver base?

FAQs: What Size Gravel to Use for Paver Base

What size gravel should I use for a patio paver base?

¾-inch crushed gravel is standard for patios.

What size gravel is best for a walkway?

½–¾ inch crushed stone, depending on traffic.

Can I use ½-inch gravel for a driveway?

Not recommended; ¾–1 inch provides better vehicle support.

Do I need a mix of gravel sizes for paver base?

A blended “¾ minus” base compacts better and reduces voids.

Will larger gravel cause uneven pavers?

Yes, stones over 1 inch may create gaps and unstable surfaces.

Can I use pea gravel for paver base?

No, it doesn’t compact sufficiently for structural support.

How deep should the gravel base be for pavers?

Patios: 4 inches, Walkways: 3–4 inches, Driveways: 6–8 inches.

What is the difference between ¾-inch and 1-inch gravel for paver base?

1-inch handles heavier loads but is harder to level; ¾-inch is standard for most uses.

Conclusion: Choosing the Right Gravel Size for Paver Base

Selecting the correct gravel size is the foundation of any successful paver project. ¾-inch crushed gravel is the standard choice, but adjustments may be needed for heavy driveways, poor soil, or freeze-prone climates. Proper layering, compaction, and drainage planning ensure a stable, long-lasting, low-maintenance surface.

Whether you’re a DIY enthusiast or hiring a professional, taking the time to calculate, layer, and compact your gravel base correctly will save money, prevent problems, and create a patio, walkway, or driveway that looks and performs beautifully for years.